Consulting

Recently Water Resources Co. was contacted by a large tuck manufacturer to solve a water purification need within their vehicle assembly line. They needed a quick option for purified water to add with glycol in a radiator assembly line. Due to location within the assembly line, a drain utility was not an option. Due to safety requirements, the area had to remain safe for factory workers.

Design

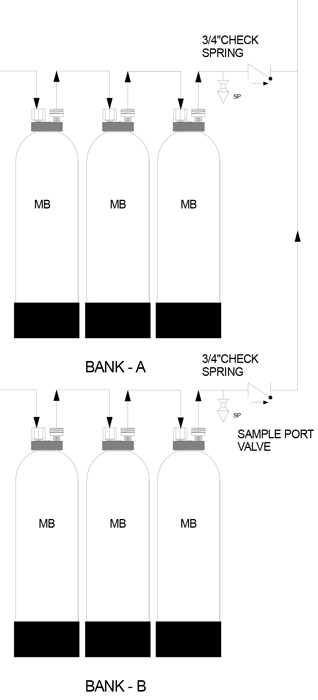

The WRC team provided recommendations for a Deionized Resin Ion-Exchange Water Purification System. Typically the “Fastest way to receive purified water” and not needing electrical and drain utility. Due to space constraints WRC provided client with drawings to determine most efficient sizing for a system and its management.

Equipment:

All meeting a deadline, WRC provided a service deionization system on the factory floor. Contentions for leak containment were provided within the installation. A water quality meter was provided along with resin strainers for filling equipment protection. System is flexible for future growth.

- April 18, 2022

- 4,306

- 0

- Water